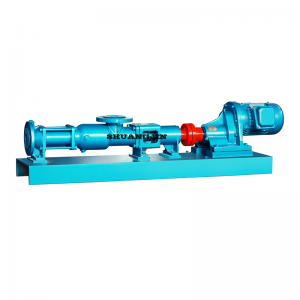

Bilge water liquid mud sludge pump

Principle

EH series is horizontal mounted and flange connected Shaped lines are designed with large eccentricity and large screw pitch, which increase the life of the lining, and reduce leakage with long sealing lines. The length of the bushings of different stages is unchanged, only the lead is changed, and the installation dimensions of the pumps of different stages remain unchanged.

It has good self-suction ability, simple structure, economical & durable, insensitive to impurity in liquid, high usability & reliability,

It has high self-priming ability with particular self-sealing performance.

It can transfer liquids with wide range of viscosity, bad fluidity liquids can also be transferred, without stir and shear, liquids with fiber or worried the crystal to be damaged can be transferred.

The capacity can be adjusted by the speed, so it is suitable to be used for special pump system with different capacity.

It has a steady capacity and the lowest pulsation shear.

It has a high efficiency, long service life, low abrasive, few parts, convenient for maintenance and replacement, lowest cost for maintenance.

Performance range

Maximum pressure:

single-stage 0.6MPa; two-stage 1.2 MPa; three-stage 1.8MPa

Maximum flow: 130m3/h

Maximum viscosity: 2.7*105cst

Maximum allowable temperature: 150℃

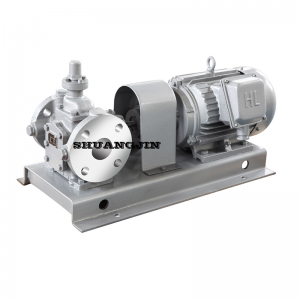

Range of application:

It can transport liquid containing fiber and solid particles, or medium containing gas. It is widely used as conveying pump in various industries such as food, petroleum, chemical industry, shipbuilding and textile, etc.

Range of application

Textile industry: Transfer for synthetic fibre liquids, viscose liquids, dye, printing ink, nylon, powder liquor etc.

Shipbuilding industry: Transfer for residue oil, stripping, sewage and sea water.

Metallurgic and mine industry: Transfer for oxide and waste water, drainage of mine and

Sewage treatment: Transfer for various industrial waste water, city sewage and sludge.

Metallurgic and mine industry: Transfer for oxide and waste water, drainage of mine and liquids explosive.