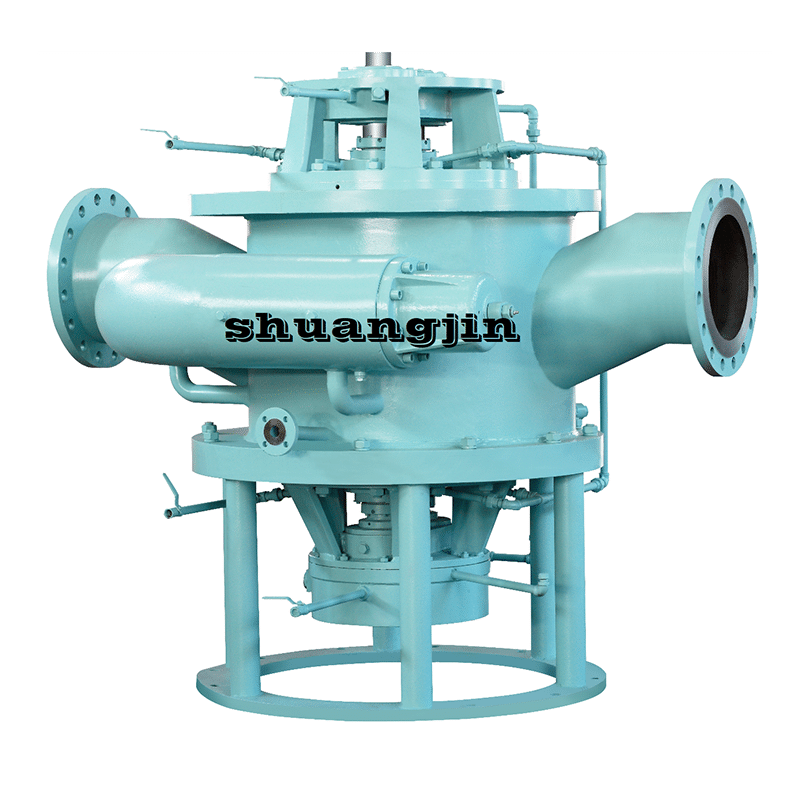

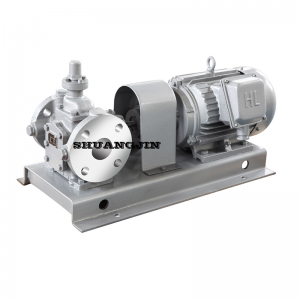

Crude Oil Fuel Oil Cargo Palm Oil Pitch Asphalt Bitumen Mineral Resin Twin Screw Pump

Maine Features

For a twin screw pump is concerned, the shaft is a key part since it needs to bear the radial force with a larger

bearing span. The pump always asks for quite higher quality of shaft, because the deformation of the shaft has

great influence on the shaft seal, bearing life, noise and vibration of the pump. The shaft strength can be guaranteed by heat treatment and machining.

The screw is the main part of twin screw pump. The size of the screw pitch may determine the pump

performance. So, the pump of a certain specification has various screw pitch to meet various needs and

therefore facilitating economic selection of pump.

The screw can be replaced individually

for less use cost. The screw can be

made with various selected materials to meet the requirements of different medium and working conditions.

Also, a pump can be modified to have different performance parameters and adapt itself to the changing

working conditions just by replacement of the screw (Changing the pitch).

The screw may undergo special treatment (surface hardening, spraying treatment, etc) to meet requirements

of special working conditions. It also makes repairing of the pumping components easy. It requires high technology for processing screw (rotator) of separate structure due to the complicated nature for interchangeability of the parts. Special machine tools and precision NC equipments are needed to guarantee the quality.

Performance

* Handling various medium without solid.

* viscosity can reach up to 8X105 mm 2 /s when reduced the speed.

* Pressure range 6.0MPa

* Capacity range 1-1200m3 /h

* Temperature range -15 -280°C

Application

* This kinds of pump is mainly used in Oil Tanker in ship building as cargo and stripping pump, load or unload oil pump. With jacketed pump casing and flushing system of mechanical system, it is widely used for high temperature asphalt, various heating oil, tar, emulsion, asphalt, and also loading and unloading various oil goods for oil tanker and oil pool.

* it is also use in ship to transfer for various acid, alkali solution, resin, color, printing ink, paint glycerin and paraffin wax.

* Oil refinery transfer for